Galvashield® Fusion® T2

Galvashield® Fusion® T2

Galvashield® Fusion® T2 is the next generation of cathodic protection for reinforced concrete that combines the power of impressed current cathodic protection (ICCP) with the maintenance-free performance of galvanic anodes.

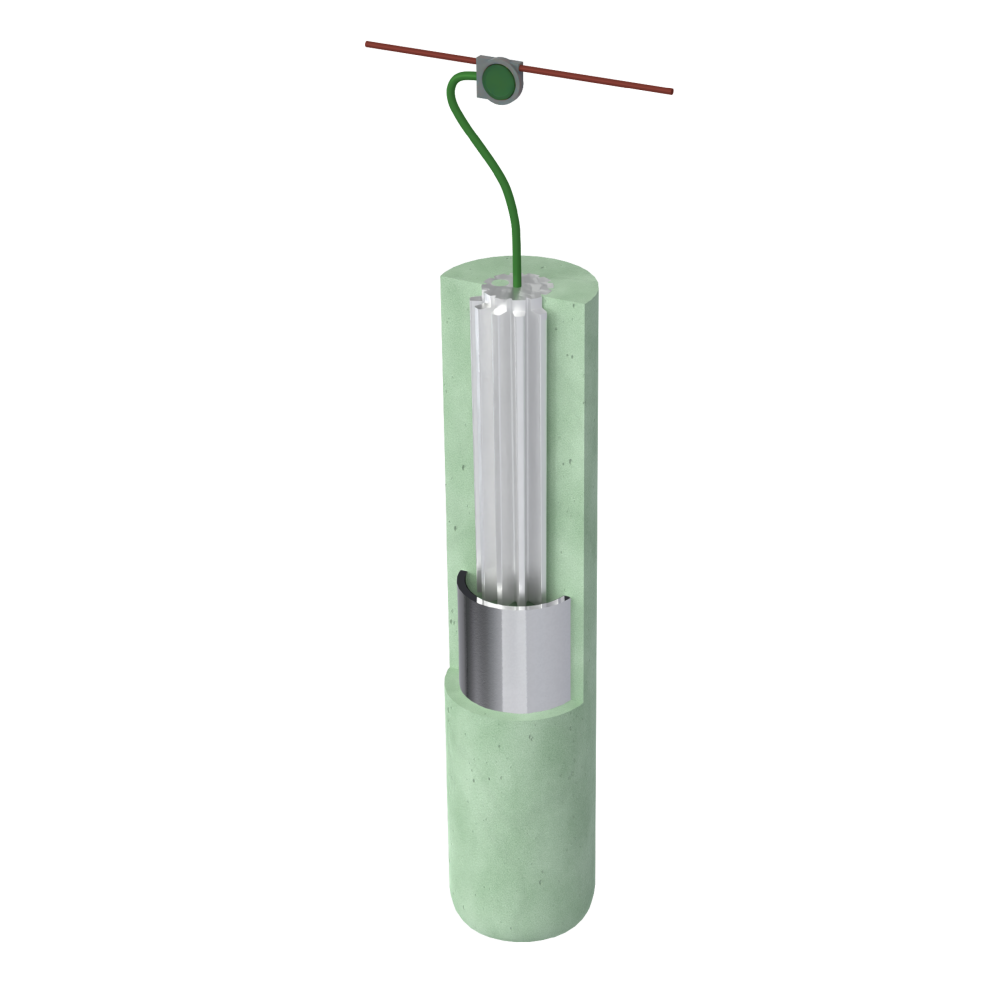

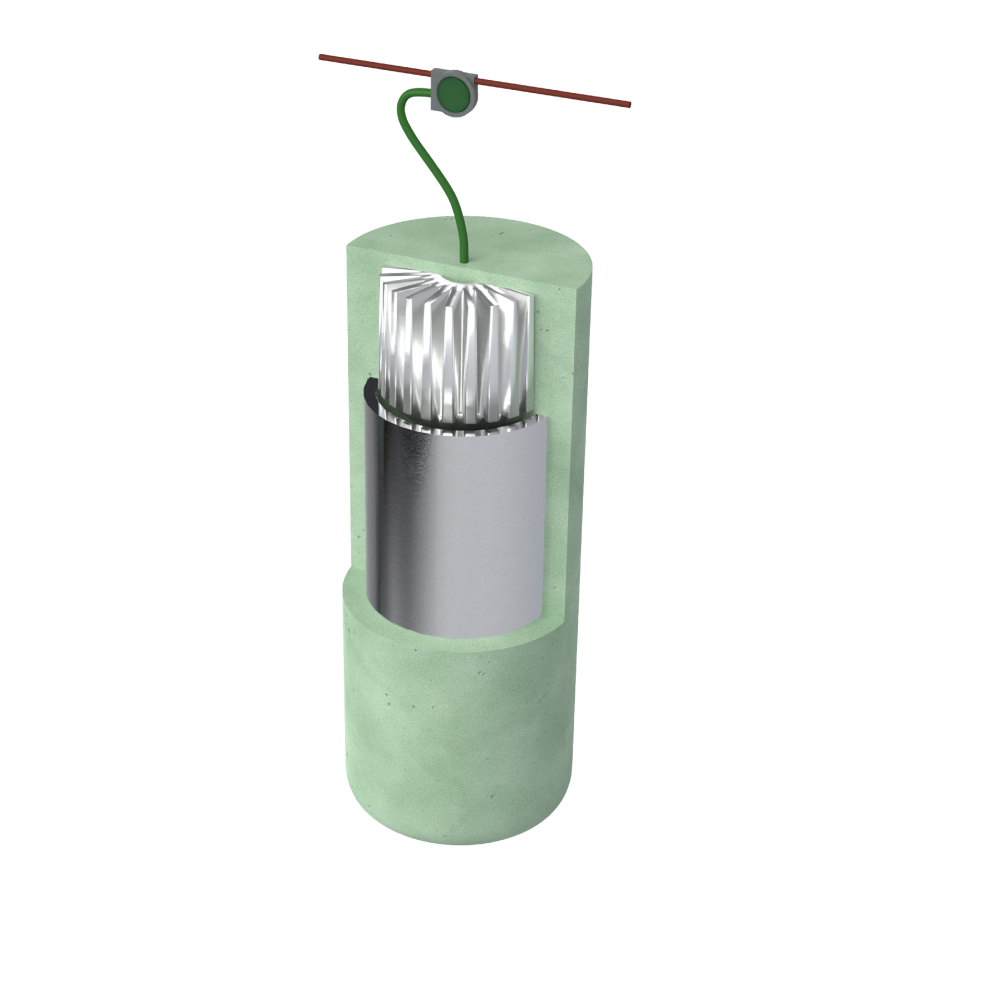

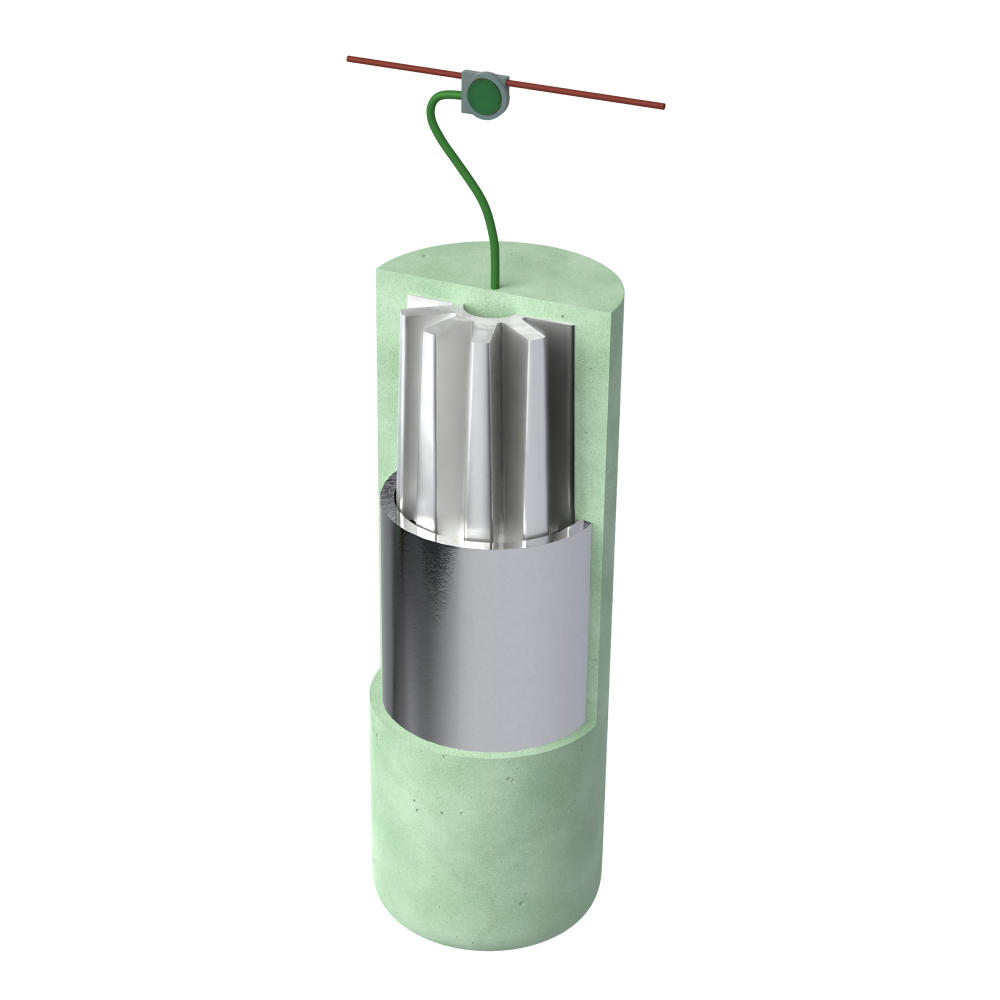

Galvashield® Fusion® T2 provides two-stage protection within a single anode unit embedded in a drilled hole.

- Stage 1 ‐ an intense burst of self-generated impressed current strikes the reinforcing steel and passivates rebar corrosion

- Stage 2 ‐ after the impressed current phase, galvanic anodes shield the structure from future corrosion damage

The anode selection and spacing are based on the specific condition of the structure. Final designs use standard cathodic protection principles in accordance with ISO BS EN 12696 and NACE RP0290 or can be based on achieving cathodic protection or passivation in Stage 1 and cathodic prevention in Stage 2.

These cylindrical anodes are quickly and easily installed into holes drilled in mechanically sound concrete and electrically connected to adjacent reinforcing steel to proactively protect actively corroding reinforcing steel. For full installation instructions, refer to the technical data sheet.

-crop_custom_3600x3600_at_0.0-0.0-scale_1000x1000.jpg)

Grout Properties

For optimum performance, use Galvashield® Embedding Mortar when grouting anodes in drilled holes to provide an ionically conductive path to the substrate.

_[WEB]-crop_custom_3600x2338_at_0.0-0.0-scale_1000x649.jpg)

Features and Benefits

- Proven Technology: ICCP electro-chemical treatment and alkali-activated galvanic anode technologies have decades of demonstrated performance.

- Long Lasting: Can be designed to provide corrosion protection for up to 30 years or more without the need for maintenance with an option to have ICCP Phase 1 repeated at any time in the future if desired.

- Targeted Protection: Ideal to provide protection to targeted areas identified as high corrosion risk, such as hot spots.

- Economical: Shortens the construction schedule due to fewer anodes being required compared to traditional galvanic anodes.

- User Friendly: Galvashield® Fusion® T2 is a single unit two stage system with no external power requirements.

- Low Maintenance: Galvashield® Fusion® T2 operates automatically once installed, reducing access requirements, time, and cost.

- Measurable Performance: While not critical for the long term operation of the system, the site performance can be measured and validated if required.

Anode Sizes

Unit | Description | Unit Size (diameter x length) | Minimum Hole Size (diameter x depth) |

|---|---|---|---|

T2 Standard | Large capacity two stage anode | 46 x 105 mm | 50 x 135 mm |

T2 Slim | Small diameter for lower steel densities and faster installation | 29 x 135 mm | 35 x 165 mm |

T2 X | Two stage anode for extreme environments | 46 x 130 mm | 50 x 160 mm |

Note: Fusion® T2 is also availabile in custom dimentions to meet customer requirements

Fusion® T2 Slim

Fusion® T2 Standard

Fusion® T2 X

Applications

- Apartment and condominium balconies

- Bridge decks, piers, abutments, piercaps and girders

- Parking decks, columns and beams

- Piers, wharves, piles, pile caps and beams in a marine environment

- Highly corrosive environments such as breweries, pulp and paper and industrial facilities

- Swimming pools and concrete tanks

Technical Documents

Select a document to download product information. For CAD drawings in DWG format please Contact Us.

Brochures

Technical Data Sheet

Installation Instructions

Safety Data Sheet

Project Examples

See how this product was used in successful projects.

Market Segments

This product has been used to solve corrosion problems across these markets.