Yaquina Bay Bridge Cathodic Protection Rehab wins ICRI Award of Excellence

Vector Corrosion Technologies Wins ICRI Award of Excellence for Cathodic Protection Work on the Hist…

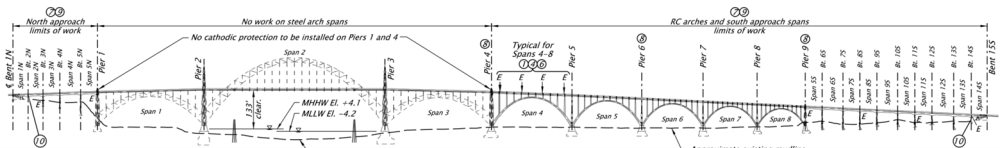

The Yaquina Bay Bridge, a testament to architectural brilliance, is not just a functional structure but a piece of history. Standing tall at 130 feet and stretching over 3,200 feet, this bridge blends concrete and steel, featuring concrete curved t-beam spans, concrete deck arch spans, steel deck arch spans, and a main steel through-arch span. The bridge’s steel members are strategically placed over the 130-foot navigational channel to facilitate maritime traffic. The construction of this historic bridge involved a massive 30,000 cubic yards of concrete and 3,100 tons of steel.

Throughout its life serving public transportation, the bridge’s substructure has been susceptible to environmental impact, including wind, salt-water spray, humidity, and temperature swings – all of which are a recipe for corrosion. Cathodic protection was installed to preserve its structural stability to promote a safe passage for public transportation.

In 1985, the Oregon Department of Transportation carried out a “carbon paint anode” impressed current cathodic protection demonstration project on the two northernmost reinforced concrete deck girder spans on the Yaquina Bay Bridge. No failure of the conductive anode was observed in 1990, five years after application, and in 2000, 15 years after application. Between August 1992 and February 1994, the bridge’s original thermally applied impressed current cathodic protection (ICCP) system was installed. This ICCP system consisted of a thermally sprayed zinc anode, also referred to as “metalizing”. The metalizing process propels molten zinc metal onto the concrete surface which acts as the ICCP anode.

The Oregon Department of Transportation selected this externally applied anode due to its application process and ease of installation around the complex geometry of the substructure. The non-destructive cathodic protection system also mimics the “concrete gray” color, an essential consideration for rehabilitating the historic bridge. In 1999, four zones on the approach spans were included in a two-year field trial of humectants to improve zinc anode performance. The humectants LiNO3 and LiBr were applied to two zones; the adjacent zones were left untreated as controls. The humectants substantially reduced circuit resistance compared to the controls.

In 2019, the Yaquina Bay Bridge rehabilitation project came out for bid. The structural repairs included new bent and pier bearings, beam seat extensions, expansion joint replacement, 5,500 linear feet of structural crack repair, seismic retrofit, removal and replacement of the existing ICCP system, and many other incidental scopes of work. The project consisted of removing and replacing roughly 320,000 square feet of zinc anode, making it one of history’s most significant ICCP projects. The project also called for 160 square yards of concrete repairs. The minimal quantity of repairs needed was a true testament to the success of the ICCP system, especially considering the harsh saltwater environment.

Installing the ICCP system was a meticulous process involving several steps. First, the sound concrete was cleaned and profiled by abrasive blasting to an ICRI CSP 4 profile. Then, a 99.99% zinc anode was applied using equipment that melts and projects the zinc onto the surface. The adhesion of the zinc anode to the concrete surface was governed by mechanical interaction as the zinc quickly cooled after making contact. Finally, impressed current was applied to the zinc anode and the internal structural steel, protecting the steel and prolonging the life of the bridge.

Project

Each arch and support span were fully scaffolded to gain access to reach every square foot of the concrete surface. The arch spans’ scaffold was supported by anchor plates and cables fastened to the deck soffit, arch spans, and spandrel columns, while the approach spans’ scaffold was supported from the soffit and directly off the ground.

Walk bridges were built and used between arch spans to provide equipment and material access. Enclosures were constructed around the scaffold to protect the public and the environment from silica and zinc exposure during the installation of the ICCP system. At the peak height of the bridge, there were as many as 17 stories of scaffolding.

Large-volume dust collectors circulated the air during blasting and metalizing. This was essential for protecting workers from silica exposure and mitigating potentially harmful fumes from melting zinc during metalizing.

Six hundred tons of abrasive media was used to remove the previously installed zinc and to clean and profile the concrete surface to accept the new zinc anode. After the abrasive blasting stage, delaminated or spalled concrete was identified for removal and replacement. Non-essential near-surface metals (tie wire, chairs, anchors, etc.) were either removed from the concrete surface or masked using a non-conductive epoxy to prevent a short in the ICCP system.

Multiple reference cells were installed in each of the designated zones to test the reinforcement’s electrical potential and ensure the proper level of protection.

Brass terminal plates were installed on the concrete surface and eventually connected to the zinc (anode), while structure connections were made to the reinforcing steel (cathode). The anode and reinforcing steel were checked and confirmed to be non-continuous.

170,000 pounds of zinc were applied using thermal arc spray to a thickness of 15-20 mils. Mechanical “pull-off” tests were performed periodically to ensure the specified bond strength was met between the anode and concrete surface.

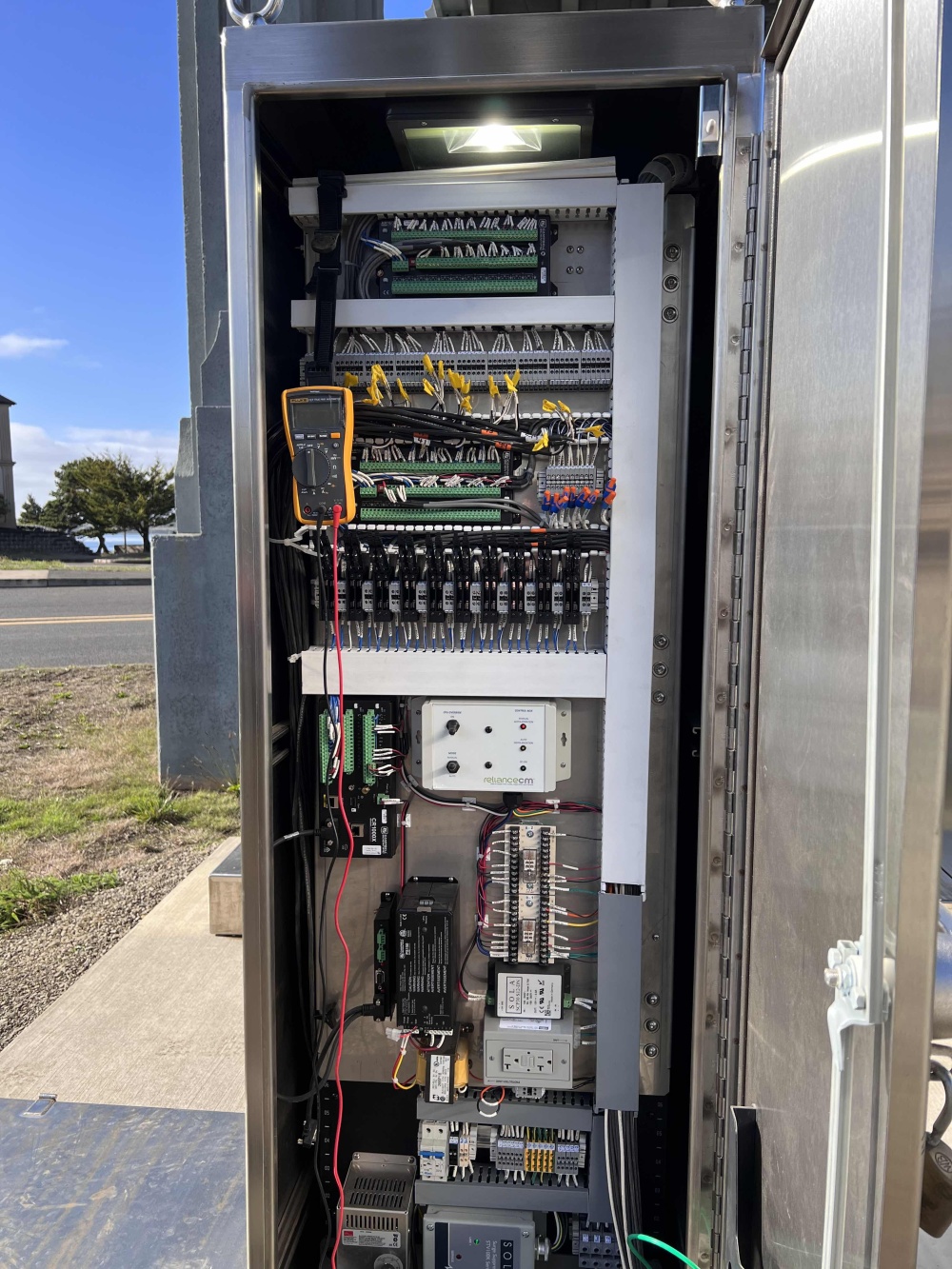

New wires were run from the anode and structure connections to low-voltage DC rectifiers that were placed on the north and south sides of the bridge approaches.

The Yaquina Bay Bridge project started in August 2020 and was completed by August 2023. Although the project was successful, it didn’t come without a few challenges, not to mention, the project started during the COVID-19 global pandemic outbreak.

Poor Air Quality from Oregon Wildfires

During the mobilization and project start, Oregon experienced disastrous wildfires. The air was tested, and the Air Quality Index showed toxic air pollutant levels caused by the smoke.

High Winds Caused Delays Along with Failed Containment

The project’s duration was characterized by the relentless impact of coastal wind and rain, which affected all contractors involved.

Suspended Work Periods Due to Protected Wildlife Nesting

Between April and July, nesting of protected wildlife was also a challenge. Work has to be suspended in areas of the bridge where nesting occurred until Animal and Plant Health Inspection Services (APHIS) deems it acceptable and nests can be removed.

Metalizing from Snooper Truck

Since the scaffold was supported by the bridge deck soffit using brackets and cables, the anchor points couldn’t be metalized while the scaffold was in place. Once the scaffold was removed, a snooper truck was utilized to access the hundreds of locations that still needed to be addressed. This work was done between midnight and 5 AM to limit the impact on commuters.

The successful completion of the Yaquina Bay Bridge rehabilitation project highlights the enduring effectiveness of innovative engineering solutions in preserving historic structures. The Oregon Department of Transportation (ODOT) extended the bridge’s lifespan by meticulously installing an Impressed Current Cathodic Protection (ICCP) system, demonstrating the system’s robust 25+ year performance in combating corrosion in reinforced concrete structures.

Opting for cathodic protection over costly removal and replacement saved significant time and resources and ensured the bridge’s structural integrity in a challenging coastal environment. This project, involving removing and replacing 320,000 square feet of zinc anode and addressing 160 square yards of concrete repairs, stands as one of the most significant ICCP undertakings in history.

Despite facing numerous challenges, including environmental impacts, wildlife nesting periods, structural access, and the constraints of the COVID-19 pandemic, the project team skillfully navigated these obstacles. The comprehensive scaffolding setup, careful handling of hazardous materials, and strategic work scheduling were pivotal in the project’s success.

The rehabilitation of the Yaquina Bay Bridge is a testament to ODOT’s commitment to preserving architectural heritage while implementing modern engineering practices. The project’s successful completion not only restored the bridge’s functionality and safety but also preserved its historical significance, ensuring that this iconic structure will continue to serve the public and stand as a symbol of engineering excellence for years to come.

These innovative products and technologies were used on this project.