Cadet Point Marina Steel Sheet Pile Corrosion Protection

The Problem

Point Cadet Marina is a major marina owned by the City of Biloxi strategically situated between the Golden Nugget Hotel & Casino and the Margaritaville Resort. As the largest marina in Biloxi, it offers 246 slips accommodating vessels up to 100 feet in length, with an approach depth of 12 feet and a dock depth of 10 feet. Developed in the 1980s to enhance waterfront tourism and recreational boating, the marina has become a vital component of Biloxi’s maritime activities.

After 40 years, the marina’s steel sheet pile seawall was suffering significant corrosion, particularly in the tidal and splash zones, due to prolonged exposure to harsh marine conditions. The absence of an effective cathodic protection (CP) system and failed coating exacerbated the problem, allowing saltwater and tidal fluctuations to accelerate the deterioration of the structure.

The extensive corrosion was compromising the structural integrity of the seawall. Immediate intervention was required to repair the damage, prevent further erosion, and safeguard the marina’s operations. Recognizing the need to protect this critical infrastructure, the City of Biloxi initiated a program to address the corrosion issues and extend the seawall’s service life.

Our Solution

To address the corrosion issues at Point Cadet Marina, a comprehensive and carefully engineered corrosion mitigation strategy was implemented. A galvanic cathodic protection (GCP) solution designed to protect the entire seawall was a key element of the plan. The GCP solution integrated a galvanic jacketing system that is commonly used to provide robust splash zone protection to concrete and steel cylinder piles with large bulk anodes in the submerged section.

The installation process included steel surface preparation, where marine growth, failing coatings, and severe corrosion buildup were removed. New steel plates were welded over the corroded holes in the sheet pile to restore structural integrity before the CP system was installed.

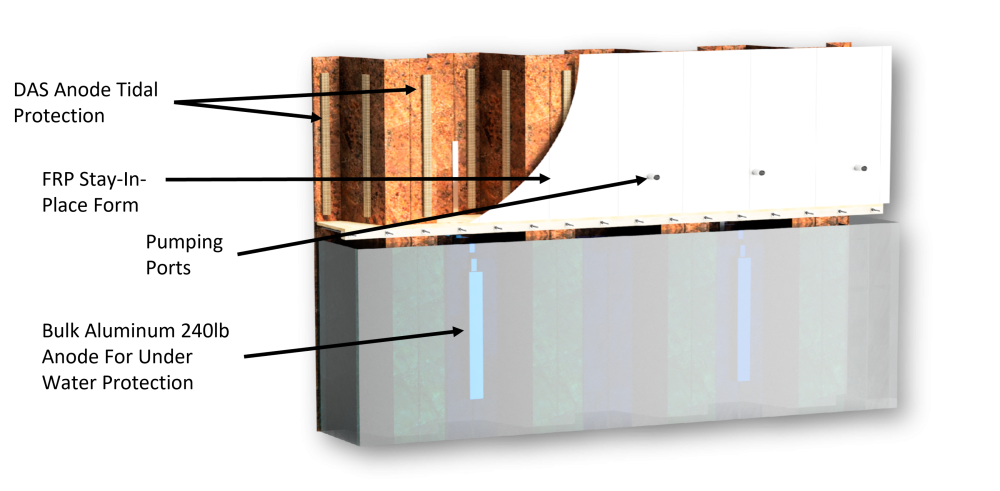

The customized Galvashield Jacket solution centered around the use of Galvashield Marine DAS (distributed anode system) inside of a stay-in-place FRP forming system with the intermediate space filled with concrete. Complementing this system, 240lb Aluminum Galvanic Bulk Anodes with extended anode cores were efficiently installed for underwater protection and minimized the need for divers. Together, the galvanic jackets and the bulk anodes formed a unified and long-lasting GCP corrosion protection strategy, designed to safeguard the steel sheet pile structure against the harsh marine environment for years to come.

A critical component of this project was the precise design of the CP system, conducted by a NACE-certified Cathodic Protection Specialist (CP4) with significant experience in GCP design for marine structures. The system was designed not only to meet the immediate cathodic protection current requirements but also to function effectively over the intended 25-year service life. This forward-thinking approach ensured that the system’s design current would still be sufficient at the end of the 25-year period. The environmental conditions were carefully considered, with aluminum bulk anodes selected for saltwater and mild brackish water environments, ensuring compatibility with the galvanic jacket system.

The Result

The implementation of the full scale galvanic cathodic protection solution including Galvashield Jackets and bulk aluminum anodes to protect the corroding steel sheet pile at Point Cadet Marina delivered substantial benefits to the City of Biloxi. By effectively repairing existing corrosion damage and employing GCP to mitigate future corrosion, the project restored the structural integrity of the seawall and extended its service life by more than 25 years. This comprehensive rehabilitation project resulted in significant time and cost savings for the City of Biloxi, while also ensuring the continued protection and operational stability of Point Cadet Marina—a key asset in Biloxi’s tourism and maritime activities.

Technology Used

These innovative products and technologies were used on this project.