Sturgeon River Bridge Rehabilitation

Originally rehabilitated in 2004 – The project consisted of considerable deck repair patches, waterproofing and paving. This interim repair plan aimed at deferring a larger, more costly superstructure replacement for a number of years.

Working with the client, R.J. Burnside & Associates proposed using this project for an A/B experiment to determine the effectiveness of Type 1 Anodes and whether there would be long-term benefits.

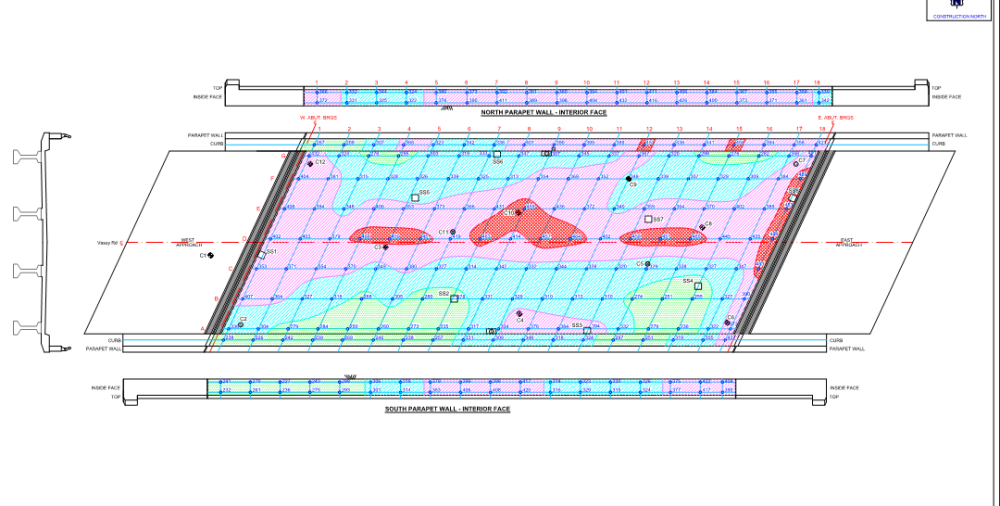

The test involved repairing the entire deck of the bridge but only placing Galvashield® XP sacrificial anodes on the south side of the bridge.

The north side was repaired with no anodes as the control.

In 2022, the County wanted to complete another rehabilitation program, so in advance of that, they completed a full condition survey of the deck, barriers, girders, and abutments.

Typically, deck repairs are completed in areas where the corrosion potential is more negative than 0.45 (dark red), which are largely on the north side where no anodes had been installed.

The pink, blue, and green areas are areas that would not typically be removed in a deck rehabilitation. This data shows how effective the anodes were at mitigating corrosion in the protected areas.

Normally, with this information, 3 options would need to be considered:

- Do nothing

- Complete another round of deck repairs

- Replace the entire superstructure (deck and girders).

The decision was made clear after the girders were evaluated in accordance with the Canadian Highway Bridge Design Code and found to be deficient, which meant a full superstructure replacement would be needed.

Thanks to R.J. Burnside pioneering a galvanic anode rehabilitation strategy, the first deck rehabilitation bought the client 18 years of additional service life, outlasting the rest of the superstructure.

"After being installed for 18 years, it was evident from the inspection that the south side of the bridge, which contained the Galvashield XP anodes, outperformed the north side, which contained no anodes. This demonstrated to us that Galvashield XP is a good investment to extend the life of concrete repairs." - Stephen Riley, P.Eng | Senior VP at R.J. Burnside

Technology Used

These innovative products and technologies were used on this project.