Coal Creek Power Station

Located about 50 miles north of Bismarck, Coal Creek Station is North Dakota’s largest power plant and distributes electricity into the twin cities of Minnesota, Minneapolis and St. Paul. Coal Creek Station operates two late 70’s vintage lignite-fired generators and combined have a capacity of more than 1,100 megawatts.

The Problem

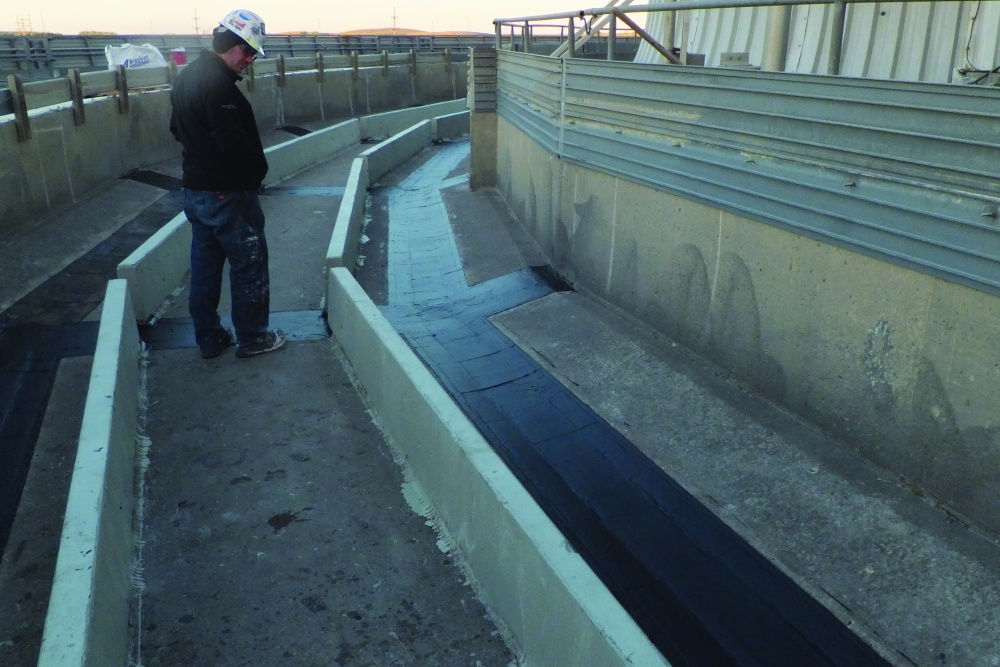

After 40 years of use, cooling tower #92 was showing its age and required lots of attention. If the entire cooling tower were demolished and rebuilt, including the interior concrete structure, it would be very costly and require extended downtime. Even though the cooling tower was showing signs of advanced deterioration, it was determined that the concrete could be preserved, so an extensive restoration and rebuild of the cooling tower was planned during an extended 6-½ week shut down in May, 2017.

Our Solution

The structure’s age, years of constant heavy use, leaking water through joints in the precast concrete hot water basin and freeze-thaw cycling were the primary sources of the concrete deterioration as evidenced by rust staining, cracking, spalling, concrete delaminations and general wear. The North Dakota environment is rather extreme, with a 181 degree Fahrenheit variation between its highest and lowest temperature, the 3rd largest variation of any U.S. State.

Galvashield® XP2 anodes were installed to mitigate patch accelerated corrosion at all interfaces of new and old concrete.

The Result

According to Great River Energy, protecting the environment has always been a priority at Coal Creek Station and in 1998 received ISO 14001 certification for its environmental management system. As a certified plant, they are committed to continuously evaluating and improving their environmental performance. Every ton of fly ash captured at Coal Creek Station and sold to produce concrete reduces the carbon dioxide produced by a portland cement kiln. Maybe not so obvious is the benefits concrete preservation provides to the environment. Extending the life and the reuse of concrete structures reduces the amount of solid waste in landfills, reduces air and thermal pollution, and conserves energy and natural resources. The galvanic protection provided by our anodes will ensure this restoration of this structure meets the owner's service life expectations.

Technology Used

These innovative products and technologies were used on this project.