Galvashield® DAS

Galvanic Anodes

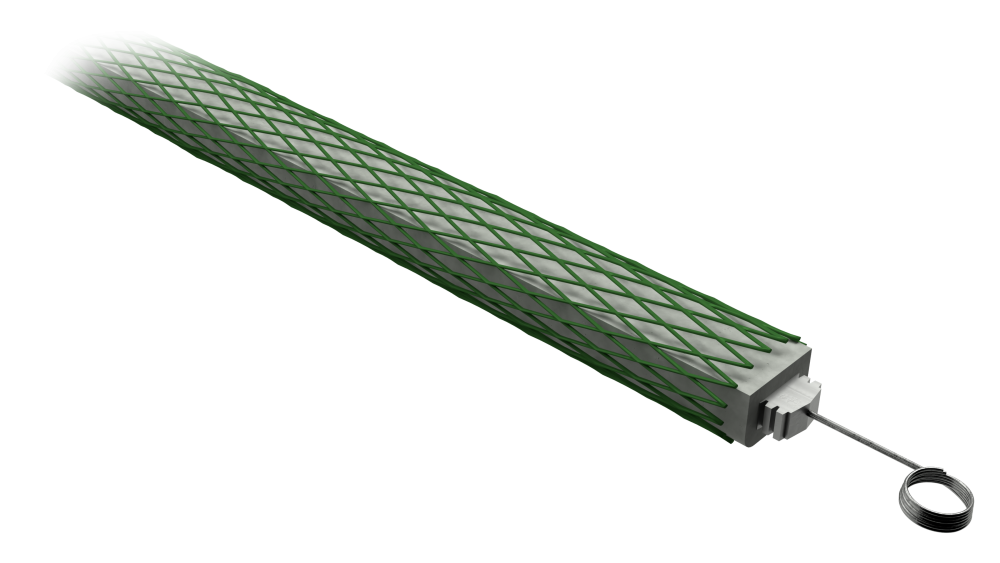

Embedded in concrete overlays, encapsulated inside reinforced concrete jackets, or used in conjuncti…

Our first active installation of the Galvashield® DAS product line in a deck overlay was in 2003 on the North Otter Creek Bridge for the Ontario Ministry of Transportation (MTO). Since then, we have monitored its performance and aggregated that data into our models and designs. This project was also the first of any galvanic system embedded in concrete to meet the criteria of the NACE Cathodic Protection Standard.

Utilizing our 20 years of experience with the Galvashield® DAS product line, we have calibrated and optimized this system for a 20-year service life to ensure performance and efficiency while maintaining its tried and true dependability.

The introduction of the Galvashield® DAS-X to our X-Series of products ensures you can get the high performance and long-term protection you need in any environment. Cathodic protection system designers should utilize DAS-X if your structure sees average annual temperatures above 15°C or 60°F or is exposed to high levels of chlorides. To learn more about the X-Factor, read our blog post here.

The new core design has also been calibrated with end-of-life performance criteria in mind to ensure you get the protection you need for as long as you need it.

When you develop your next cathodic protection system, we recommend utilizing our new Performance-Based Sample Specification to ensure that the products used on your structure are proven to provide the level of protection you prescribe.

Visit the Galvashield DAS product page for updated datasheets, drawings and guide specifications or contact your Vector Technical Representative.

Reinforced concrete forms the backbone of our modern world. Yet, the very element that strengthens i…

World of Concrete Announces the 2025 Innovative Product Award Winners : The third annual awards …

Pacific Ports Magazine October/November 2024 — It is with great pleasure that the Association o…