Galvashield® SM-DAS Wins Innovative Product Award

World of Concrete Announces the 2025 Innovative Product Award Winners : The third annual awards …

Pacific Ports Magazine

October/November 2024

—

It is with great pleasure that the Association of Pacific Ports welcomes Vector Corrosion Technologies as our newest Associate Member. Representing the company and its team of over 70 professional engineers, technologists, business development managers, manufacturing technicians, support staff and field personnel, Carla Neal, Business Development Manager, described the innovative and unique approach to they take to extend the life of concrete structures for customers in a variety of industry sectors.

The story of Vector Corrosion is really the story of David Whitmore, President and Chief Innovation Officer. At the age of 19, Whitmore joined Vector Construction — a Manitoba, Canada company focused on highway grading, dam building, site development, and other heavy construction projects. His first project was to work on the Seven Sisters hydroelectric generating station restoration.

Years later, Dave led the first ever electrochemical chloride extraction project in North America and that experience opened his eyes to the world of corrosion, reinforced concrete and cathodic protection. In 1999, he formally established Vector Corrosion Technologies in Northern America, introducing its flagship product the Galvashield® XP, and the rest is history.

Today, with offices in Canada, the U.K., United Arab Emirates, Indonesia, Australia and the United States, Vector Corrosion serves thousands of clients around the world in various market sectors — bridges and tunnels, buildings, energy and power, industrial, parking, rail, sewer and water, and of course, marine.

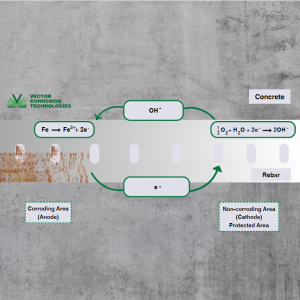

The most corrosive, naturally occurring environment on the planet is a marine tidal zone. With an abundance of chloride, moisture, and oxygen, this environment can have devastating effects on reinforced concrete structures. To address the challenges many ports and marine-related businesses face, Vector Corrosion has spent over 25 years developing a series of products and treatments, ranging from galvanic anodes, impressed current cathodic protection, fusion technology, electrochemical treatments, post-tension solutions, exposed steel corrosion protection and steel reinforcement alternatives.

Vector Corrosion received their first patents in 1999 and launched the Galvashield XP anode series — a range of embedded galvanic anodes that are used to mitigate ongoing corrosion and prevent the initiation of new corrosion activity in reinforced concrete structures. The cylindrical anode is quickly and easily installed into drilled holes in concrete that is mechanically sound but has ongoing corrosion activity. Once installed, the zinc anode corrodes preferentially to protect the adjacent reinforcing steel. Looking specifically at the marine industry, Vector’s track record shows great success for marinas, bridges, piers, tunnels, seawalls, locks and many more structures that one would find exposed to salty marine environments.

To highlight just a few recent projects:

• Bair Island Marina in Redwood City, California — severe corrosion of the steel waler was preventing the sheet pile wall from overturning. A new structural beam encasement was needed to replace lost capacity and control corrosion over the existing waler. Engineers were concerned that the steel waler would continue to corrode after the new structural beam was cast around it. Vector Corrosion recommended Galvashield® DAS Type M anodes to control the corrosion and prevent the new structural concrete beam from deteriorating.

• City of Astoria waterfront bridges — The City of Astoria removed and replaced six deteriorating timber bridges used to carry Astoria Waterfront Trolley pedestrians and vehicle traffic to waterfront businesses. The replacement structures were designed with precast concrete pile caps on steel pile foundations to meet a 75-year design life in a marine environment. Vector provided a 75-year cathodic protection design involving bulk anode sleds to protect the pipe piling, and DAS Type F Anodes installed into the precast concrete pile caps to proactively protect the embedded reinforcing steel.

• Manila International Container Terminal — An evaluation of the port’s infrastructure brought to attention signs of reinforcement corrosion to multiple structures, including concrete piles, beams and slabs. This was due to the corrosive marine environment experienced at every seaport in the world. Vector was engaged and removed areas of unsound concrete and installed Galvashield® XP4 anodes to protect the structures from further corrosion. Approximately 30,000 XP4 anodes were embedded within repairs, overbuilds and enlargements of slabs, beams, pile caps and piles. The result has extended the service life of these structures beyond the owners’ required service life.

What really sets Vector Corrosion Technologies apart is their commitment to education and advancement of the industry through professional associations where they can share best practices and innovations in the field of concrete preservation. To name just a few of the associations where Vector’s participation has added to the overall discourse on corrosion protection include the American Society of Civil Engineers, the American Concrete Institute, the Transportation Association of Canada, the National Council of Structured Engineers Associations (NCSEA) and many more.

In addition to education seminars where Vector’s professional team of concrete preservation specialists provideinformation about the concrete preservation process, its benefits, the test methods and their complete range of corrosion mitigation technologies for reinforced concrete structures, Vector has an excellent on-line resource (as well as published articles in trade and association journals) covering many topics related to the assessment, repair and service-life extension of concrete structures. The educational videos are available for download at vector-corrosion.com/about-us/education/. Vector is also a founding member of the Concrete Preservation Alliance, which hosts monthly educational webinars (certified for PDH credits through the NCSEA) as well as articles and whitepapers with the goal to provide engineers and owners meaningful and accurate information about concrete repair, corrosion mitigation and restoration. You can check out their most recent series at https://www.wesavestructures.info/Webinars.

One final — but certainly not least notable aspect of this company — Vector Corrosion has been recognized through numerous awards, most recently, the Award of Excellence from the International Concrete Repair Institute (ICRI) for their work on the Yaquina Bay Bridge in Newport, Oregon; and Project of the Year award for the Third Avenue Bridge project in Minneapolis.

The APP looks forward to working with Vector Corrosion Technologies to further our mandate of sharing best practices with Members.

—

To read the rest of this issue of Pacific Ports Magazine, click here.

World of Concrete Announces the 2025 Innovative Product Award Winners : The third annual awards …

Vector Corrosion Technologies Wins ICRI Award of Excellence for Cathodic Protection Work on the Hist…

Why Does Corrosion Happen? : Understanding Corrosion of Steel in Concrete Structures : Welcome to …